INDUSTRIAL VACUUMS FOR PRINTED CIRCUITS

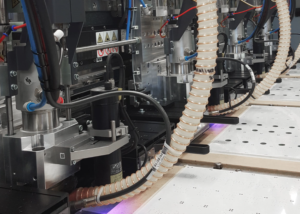

The high level of technology and the constant growth of experience that has always characterized the company iVision, have led us to develop a new range of industrial vacuum cleaners with side channel turbines, dedicated to machines that produce printed circuit boards such as drilling machines, milling or contouring, that need an accurate and efficient suction of chips/powder to achieve maximum accuracy during the work process and a perfect end product.

The line dedicated to this sector is particularly versatile and complete; it includes vacuum cleaners for single-spindle and multi-spindle machines, with centralized vacuum systems for managing an entire production facility, thus offering its customers a wide choice in order to suit every need.

THE MOST ADVANCED TECHNOLOGY IN THE MARKET

Numerous tests, hi-tech patents, and careful monitoring of details allows iVision Srl to be among the reference global suppliers in this product sector. The excellence of the design and construction techniques create a highly flexible material handling system, able to adapt to customer needs.

Numerous tests, hi-tech patents, and careful monitoring of details allows iVision Srl to be among the reference global suppliers in this product sector. The excellence of the design and construction techniques create a highly flexible material handling system, able to adapt to customer needs.

The vacuums are on wheels with centralized systems easy to use and virtually maintenance-free with innovative technical solutions, this is used to protect the units over time.

Optional accessories, such as the touch screen system, were developed specifically for the printed circuit industry.

VACUUMS BY MEASURE

In order to meet your needs, all of our vacuums are on wheels (also our centralized systems), and our containers for the collecting of chips can be of various capacities. Starting from the smallest models, that are compact and manageable for one quick emptying process and easily moveable, up to the big collection containers of 1,000 liters for heavy duty work.

For large businesses requiring 24-hour production, iVision produced a centralized system with a continuous unloading cycle mediated by a rotary valve.

iV1 PCB

INDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

IV1 PCB line vacuum cleaners are the most compact of the iVision range. We have produced a specific range of industrial vacuum cleaners with side channel turbine, used with great success in the world of PCB manufacturing. The waste generated on drilling or milling machines require particularly efficient and constant industrial aspiration for a final product, precisely called PCB (Printed Circuit Board) that guarantees of micron tolerances and that during its processing is entirely free from chips or dust. In addition to the wide range of side channel turbine vacuum cleaners, iVision has created and even patented a range of special accessories for the world of printed circuit associated to IV1 line PCBs, which make our products the best solution, and indispensable for all PCB manufacturers.

The very low noise level, ease of maintenance, as well as the design and use of Italian products, are the key features of iVision industrial vacuum cleaners.

iV2 PCB

INDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

IV2 PCB line vacuum cleaners are the best sellers among the wheeled vacuums of the iVision range, and are used for intensive collection of chips and dust generated by the drilling and milling machines with 2 to 6 spindles. This new and innovative range of industrial vacuum cleaners with side channel turbine, is used with great success in the world of PCB manufacturing in Europe, the USA, and in Asian countries led by China and South Korea. The waste generated on drilling or milling machines require a particularly efficient industrial aspiration and especially constant for a final product, precisely called PCB (Printed Circuit Board), which guarantees the minimum tolerances (in terms of Micron) and that during its processing is completely free of chips or powder, this is an obtainable condition thanks to the latest technologies available on the iV2 PCB vacuum cleaners. In addition to the already wide range of vacuum cleaners with side channel turbine, iVision has also developed and patented a range of special accessories for the printed circuit industry that make our products, quieter, simple and economic in the maintenance, ideal and indispensable for every PCB manufacturer.

iV3 PCB

INDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

iV3 PCB line vacuum cleaners are the most powerful among the wheeled vacuum cleaners and are utilized for the collection of chips and dust in the drilling machines and large milling machines (6-8 spindles). These industrial vacuum cleaners can be used, in their customized version, also with frequency inverter and be transformed into real centralized vacuum systems. Both in Europe and in the United States, but also in the countries which become a leading manufacturer of PCBs since the 2000. The waste generated on drilling or milling machines require effective and constant industrial aspiration in time, so as to be able to guarantee quality to the final product, the PCB (Printed Circuit Board) must ensure minimal tolerances (in terms of Micron) and during their processing, be completely free from chips or dust removed, thanks to the latest technologies available on the iV3 PCB vacuum cleaners all of this is possible.

In addition to the industrial vacuum side channel turbine, iVision has designed, produced and patented a range of special accessories for the printed circuit industry that make all our products ideal and indispensable for all PCB manufacturers.

iV CUSTOM PCB

INDUSTRIAL VACUUM CLEANERS FOR FIBERGLASS AND ALUMINIUM

The iV Custom PCB vacuum consist of a cyclonic pre-filter, a central unit with turbine, an integrated filter, an electrical panel with inverter and all necessary components in the management of PLC control with color screen. The system is also equipped with a powerful silencer to ensure full compliance with international standards.

The iV Custom vacuum cleaners are, for all intents and purposes, a centralized system and are among the most technologically advanced systems available on the market, and are not comparable to any of the traditionally known systems.

The long experience of iVision staff, as well as a willingness to meet customer demand, have led to the development of high-tech products as well as customized solutions. Thanks to a frequency inverter of these filters iV Line Custom PCB can manage as efficiently as 15 CNC machines simultaneously.

A sophisticated control sensor (optional) is able to measure the deterioration of the filter of the vacuum cleaners. iV Custom PCB, greatly reducing maintenance and ensuring a steady income and a permanent central vacuum.

A dedicated control system, which allows control of all functions, allows iVision to be the only company in the world that can offer optionally up to a 5 year warranty on the entire centralized system.

PRINCIPAL ADVANTAGES

The principal advantages of the PCB line are:

- Ability to modulate the frequency of the motor and thus optimize the consumption of electricity according to the real requirements of the machine

- Suction pump with high efficiency side channel turbine specifically developed for this type of machine, which are equipped with safety valves

- Touch screen – able to clearly and easily indicate the level of dirt of the filter; this data can be sent directly to the machine tool control panel and thus start the automatic filter cleaning procedures

- Optional cleaning kit that can be utilized by the operator for cleaning the machine after work.

- Increase in the production of the operator thanks to the minimal level of maintenance

ACCESSORIES