Micro Machining Process (MMP) Surface treatment

MMP is considered a special polishing process providing hyper-smooth surfaces. Tools treated with this method have a significantly better surface finish than conventional polished tools.

Treatment is completed according to a special mechanical-physical-catalytic procedure. The machine creates a high-energy movement which brings the aggregated particles into relative motion.

MMP not only dramatically improves the performance of the tool but it also dramatically impacts the performance of the tool and tool life, while also reducing production costs.

Unlike our competitors, this process is completed IN-HOUSE at the factory – this allows for lower cost and quicker turn.

MARKETS:

- Cutting Tools

- Aerospace & Energy

- Forge, Stamping and Dies

- Additive Manufacturing

- Medical

- Plastic Injection Molds

- Transmissions

APPLICATIONS:

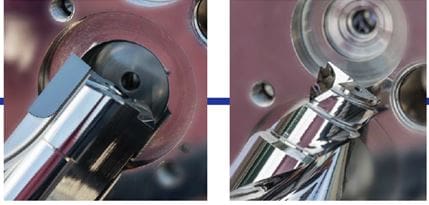

- Deep Hole

- Forming taps

- High performance inserts

- Milling cutters for nickel and titanium alloys

SUITABLE FOR:

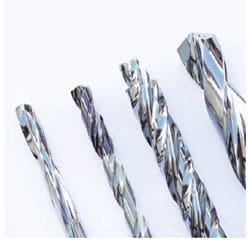

- Solid carbide tools

- Solid carbide tools with CVD and PVD coating

- PCS-equipped tools with the basic body made of carbide

- Standard and special tools from nominal – ø 0,5 mm and shank ø 3,0 mm

ADVANTAGES:

- Optimal chip removal

- Higher cutting feeds and speeds

- Reduction of built up edges – reduced cutting forces

- Less heat generation on the tool and workpiece

- Defined cutting edge rounding

- Homogeneous and reproducible surfaces can be reached