Description

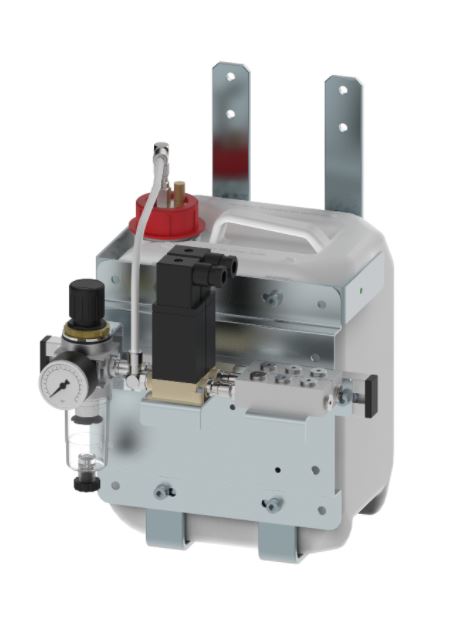

TCJ Series

External Lubrication

Scope of delivery:

The valve and container assembly consists of a PE storage container (2.5 L / 5 L / 10 L / 25 L) with bracket for wall mounting and a valve assembly with maintenance unit.

Depending on the variant, a spray head or up to 3 or 6 groups of spray heads can be connected.

Advantages:

- Reduction and avoidance of contamination in your process.

- Increased ease of use due to the separate control of the air and liquid supply

- Our 10 and 25 liter systems are adapted to standard liquid containers. This enables the container to be changed directly – without the hassle of decanting.

The result: no dirt in the container and an optimally functioning process for you.

Application area:

- Universally suitable for all applications in which low-viscosity media are used

Function:

The unfiltered and non-oiled network air (4 – 9 bar) is connected to the maintenance unit. The spray air pressure is set on the pressure reducer. We recommend a low spray air pressure of 0.5 to max. 1.5 bar.

The 24 V DC solenoid valves in the air and liquid line mean that the valve and container assembly can be attached up to max. 1,000mm above and below the spray heads possible.

Spray start, spray duration and spray end are determined by activating the valves from the customer’s control.

The TCJ series can optionally be equipped with a float switch (signals pre-warning – empty).

Our sales department will be happy to help you with further designs and special solutions. Contact Meghan for more information mlee@carbiderelatedtech.com